Products

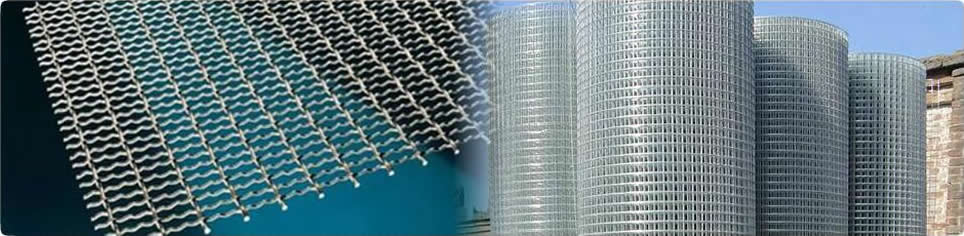

- Stainless Steel Welded Wire Mesh Rolls

Stainless Steel Welded Mesh Panels - Hardware Cloth

- Chicken Wire

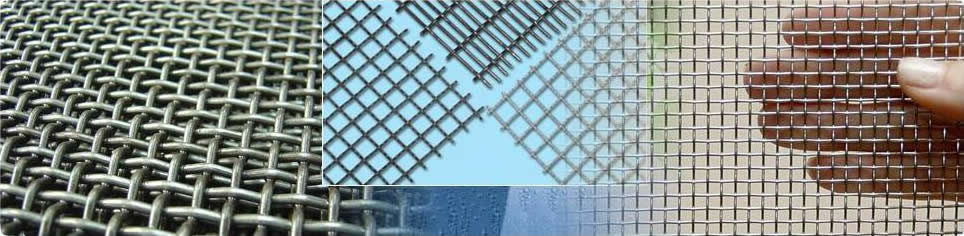

- Woven Wire Screens Woven Wire Mesh

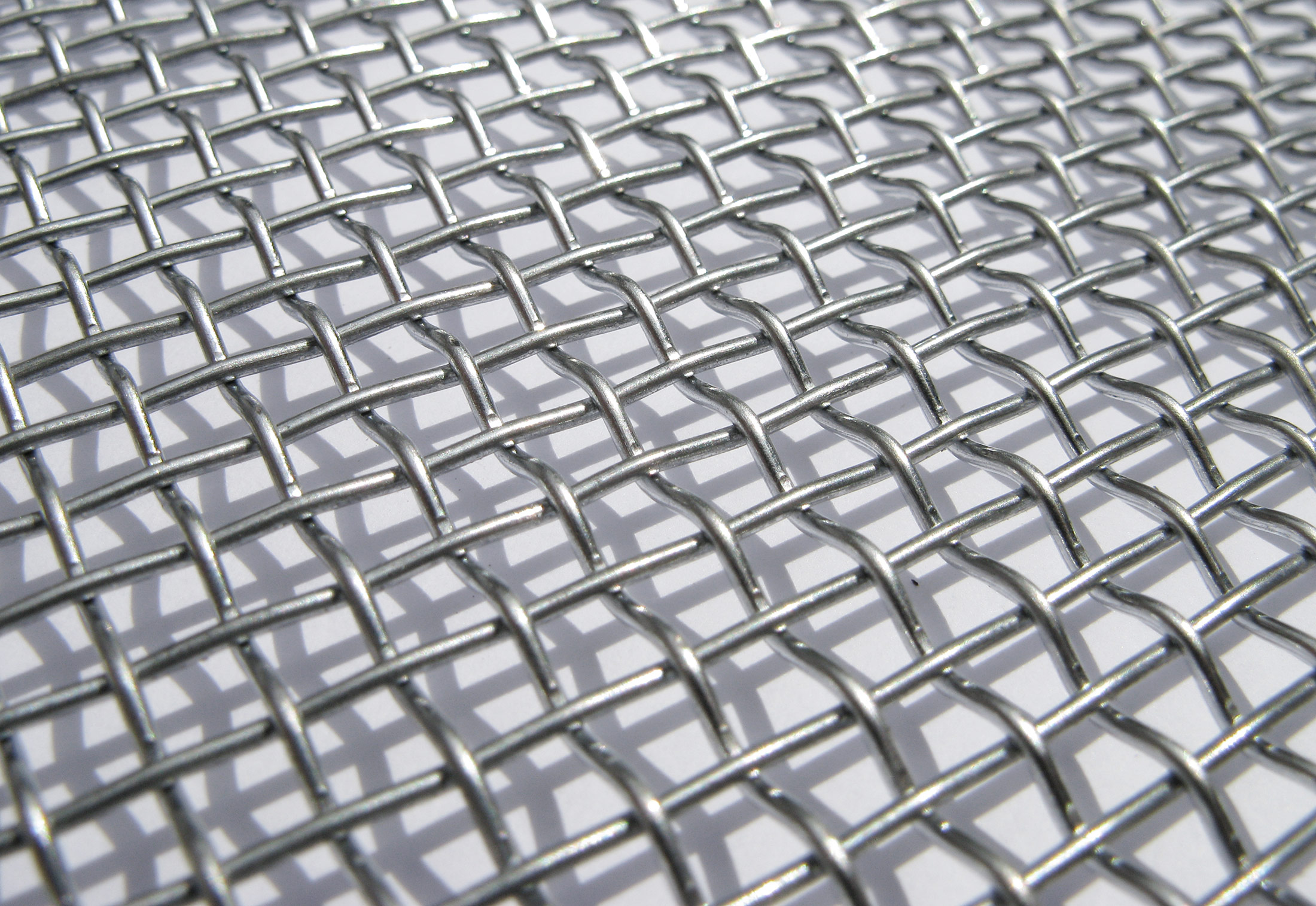

- 65 Mn High Carbon Steel Crimped Wire Mesh

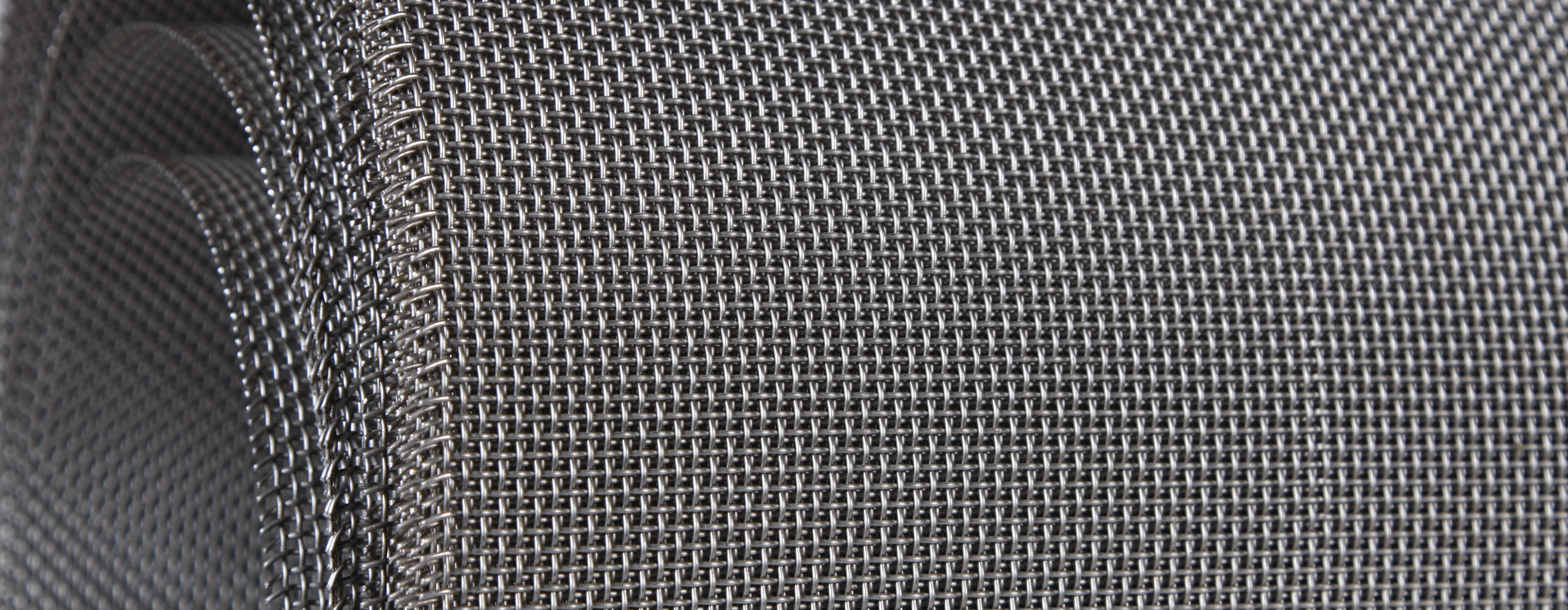

- Stainless Steel Wire Mesh

Stainless Steel Wire Cloth - Nickel Wire Mesh

- Stainless Steel Ferrule Cable Mesh

- Decorative Wire Mesh

- Architectural Woven Mesh

- 99.99% Purity Silver Woven Wire Mesh

- Molybdenum Wire Mesh

- Tungsten Wire Mesh

- Titanium Wire Mesh

- Hastelloy Wire Mesh

- Brass Wire Mesh

- Phosphor Bronze Wire Mesh

- Red Copper Wire Mesh

- Duplex Stainless Steel Wire Mesh

- Super Wide Stainless Steel Wire Mesh

- 904L Stainless Steel Wire Mesh

- 430 Stainless Steel Wire Mesh

- Selvage Edge Stainless Steel Wire Mesh

- 321 and 347 Stainless Steel Wire Mesh

- Epoxy Coated Mesh for Filters

- Stainless Steel Security Screen Mesh

- Monel Wire Mesh

- Inconel Wire Mesh

- Wire Mesh Belt

- Knitted Wire Mesh

- Expanded Metal

- Wire Mesh Fence

- Chain Link Fence Roll

- Welded Wire Mesh Panels

Products

321 and 347 Stainless Steel Wire Mesh

321 Stainless Steel Wire Mesh

321 Stainless Steel Wire Mesh – Alloy Overview

Type 321 stainless steel wire mesh is similar to the basic T-304 stainless steel alloy, but includes the addition of titanium for improved oxidation and general corrosion resistance. Compared to T-304L, T-321 stainless steel has both higher creep strength and stress rupture capabilities, and similarly possesses good low-temperature toughness. That said, T-304L wire mesh is usually more readily available than T-321, and is often used in most situations unless the wire mesh is to be used in an operating environment with temperatures above 925°F (as T-321 has better hot strength properties). If the requirement is only for resistance to intergranular corrosion after welding, then T-304L is the preferred alloy given its wider stock availability. Some characteristics of 321 stainless steel wire cloth which dictate its use are:

- Austenitic stainless steel.

- Non-magnetic when annealed.

- Slightly magnetic when cold worked.

- Withstands outdoor exposure without rusting.

- Excellent oxidation & corrosion resistance in broad range of industrial and chemical settings.

- Resists oxidation at 1500°F temperatures.

- Heating permitted between 900°F – 1600°F temperatures.

- Can be cut, formed, and welded.

Industries & Applications

T-321 stainless steel wire cloth is principally used in oil field & refinery, mining & quarrying, and aerospace industries. T-321 wire cloth is also commonly used in the chemical processing industry. Additional industries and applications which commonly use T-321 stainless steel wire cloth include:

SUBMIT RFQ

- Food Processing

- Liquid Filtration & Particle Separation

- Pressure Vessels

- Waste Treatment

Common Aliases

Type 321 stainless steel is also commonly referred to as:

- T-321

- SS321

- UNS S32100

- SUS321 (Japan)

321 Stainless Steel Wire Mesh – Typical Chemistry

UNS S32100 - 321 Stainless Steel Wire Mesh - Typical Chemistry |

|||||||||||||

Alloy |

Standard(s) |

Limits |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

Ti |

Cu |

S32100 |

ASTM A580 |

Min |

0 |

0 |

0 |

0 |

0 |

17 |

9 |

|

|

5xC |

|

Max |

0.08 |

2 |

0.045 |

0.03 |

1 |

19 |

12 |

|

|

|

|

||

AMS 5689 |

Min |

0 |

0 |

0 |

0 |

0.4 |

17 |

9 |

0 |

0 |

5xC+N |

0 |

|

Max |

0.08 |

2 |

0.04 |

0.03 |

1 |

19 |

12 |

0.75 |

0.1 |

0.7 |

0.75 |

||

347 Stainless Steel Wire Mesh

347 Stainless Steel Wire Mesh – Alloy Overview

Type 347 stainless steel wire mesh is similar to the basic T-304 stainless steel alloy, but includes the addition of niobium (formerly called columbium) and tantalum. The niobium content allows for the elimination of carbide precipitation / intergranular corrosion, and also supports superior corrosion resistance vs. even that of T-321. The combination of the chromium and tantalum additions give T-347 stainless steel wire cloth excellent creep and stress rupture properties when compared to T-304L. T-347 is usually selected over T-321 in many aqueous and other low-temperature environments. Some characteristics of 347 stainless steel wire cloth which dictate its use are:

- Austenitic stainless steel.

- Non-magnetic when annealed.

- Slightly magnetic when cold worked.

- Withstands outdoor exposure without rusting.

- Excellent oxidation & corrosion resistance in broad range of industrial and chemical settings.

- Resists oxidation at 1500°F temperatures.

- Heating permitted between 800°F – 1500°F temperatures.

- Can be cut, formed, and welded.

Industries & Applications

T-347 stainless steel wire cloth is principally used in applications where other stainless steel alloys (i.e. T-304L) are susceptible to intergranular corrosion (so the weld and the base metal are equally corrosive resistant). The primary applications are oil field & refinery, mining & quarrying, and aerospace. Additional industries and applications which commonly use T-347 stainless steel wire cloth include:

SUBMIT RFQ

- Food Processing

- Liquid Filtration & Particle Separation

- Pressure Vessels

- Steam Piping

- Waste Treatment

Common Aliases

Type 347 stainless steel is also commonly referred to as:

- T-347

- SS347

- UNS S34700

- SUS347 (Japan)

347 Stainless Steel Wire Mesh – Typical Chemistry

UNS S34700 - 347 Stainless Steel Wire Mesh - Typical Chemistry |

|||||||||||||

Alloy |

Standard(s) |

Limits |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

Cu |

Nb |

Ta |

S34700 |

ASTM A580 |

Min |

0 |

0 |

|

0 |

0 |

17 |

9 |

|

|

10xC |

|

Max |

0.08 |

2 |

|

0.03 |

1 |

19 |

13 |

|

|

1.1 |

|

||

ASTM A313 |

Min |

0 |

0 |

0 |

0 |

0 |

17 |

9 |

|

|

10xC |

|

|

Max |

0.08 |

2 |

0.045 |

0.03 |

1 |

19 |

13 |

|

|

|

|

||

AMS 5674 |

Min |

0 |

0 |

0 |

0 |

0 |

17 |

9 |

0 |

0 |

10xC |

0 |

|

Max |

0.08 |

2 |

0.04 |

0.03 |

1 |

19 |

12 |

0.75 |

0.5 |

1.1 |

0.05 |

||

|

|

|

|

|

|